In today’s dynamic industrial and commercial landscapes, the demand for dependable electrical solutions has grown significantly. Efficient distribution and reliable connections are no longer optional; they are essential for seamless operations. Facilities ranging from factories and warehouses to outdoor sites require systems that not only ensure safety but also adapt to complex electrical demands. While some may consider temporary setups sufficient, experienced operators understand that investing in robust, well-engineered equipment safeguards both productivity and personnel.

Electrical distribution in outdoor or semi-exposed locations presents unique challenges. Weather conditions, fluctuating temperatures, and variable load demands necessitate resilient enclosures that maintain performance without compromising accessibility. Outdoor Electrical Distribution Panel units are often equipped with corrosion-resistant surfaces, reinforced mounting options, and versatile connection interfaces. These panels allow technicians to perform maintenance efficiently while minimizing downtime. Careful consideration in material selection ensures that panels resist environmental wear, extending operational life significantly.

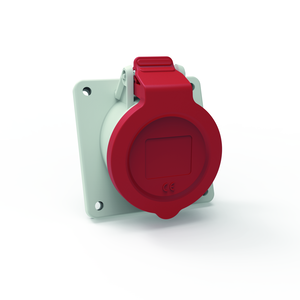

Industrial workspaces demand a variety of connection types. While traditional sockets serve general purposes, specialized arrangements offer improved efficiency. Angled Panel Mounted Industrial Socket designs provide easier reach in confined or awkward positions, reducing strain during repetitive tasks. Similarly, Distribution Socket Box solutions allow for centralized connection points, simplifying wiring layouts while maintaining organized pathways for multiple circuits. These solutions emphasize safety with protective covers and insulating materials that guard against accidental contact, while modular construction facilitates future expansion.

When selecting electrical housings, several factors influence long-term usability and safety:

Material Strength: Stainless steel or industrial-grade polymers resist corrosion, impact, and prolonged exposure to harsh conditions.

Ease of Installation: Pre-drilled mounting options, lightweight configurations, and compatible accessories streamline the setup process.

Accessibility: Doors, panels, or removable covers allow technicians to reach components quickly, enhancing response during maintenance.

Safety Mechanisms: Lockable closures, insulation, and protective barriers reduce the risk of accidents in high-traffic environments.

Modular industrial mcb box designs contribute to flexible circuit management, allowing facilities to scale without major reconfiguration.

To illustrate common setups, here’s a table highlighting typical equipment placement and recommended features in industrial spaces:

| Location | Recommended Housing | Key Feature | Benefit |

|---|---|---|---|

| Outdoor Yard | Weatherproof Panel | Corrosion-resistant coating | Long-lasting durability |

| Assembly Line | Angled Socket Unit | Ergonomic reach | Reduces operator fatigue |

| Maintenance Zone | Compact Distribution Box | Modular design | Simplifies circuit management |

| Storage Facility | Enclosed MCB Box | Lockable access | Enhances safety and control |

Structured placement ensures that equipment aligns with operational priorities while providing safe, accessible connections for staff across multiple zones.

Innovative design in electrical distribution goes beyond mere appearance. Features like angled sockets reduce repetitive motion, while clearly labeled panels improve response time during troubleshooting. Lightweight enclosures, yet sturdy in construction, offer portability for temporary setups such as outdoor events or seasonal projects, without sacrificing performance. Modular interiors allow technicians to replace or upgrade individual components instead of the entire unit, reducing cost and downtime.

Different work environments impose distinct requirements:

Industrial Plants: Continuous operation demands robust systems that withstand heavy usage.

Construction Sites: Exposure to dust, debris, and moisture requires resilient protective housings.

Event Venues: Flexibility and rapid deployment matter as electrical setups often change locations.

Warehouses: Organized connections help maintain workflow efficiency while ensuring safety compliance.

By considering the unique context of each environment, operators can select suitable solutions, optimizing both functionality and longevity.

Routine inspections and preventative maintenance are integral for sustained performance. Features that simplify maintenance, such as hinged doors or removable panels, enable quick assessments. Many modern enclosures incorporate visual indicators or accessible compartments for circuit breakers, allowing staff to identify issues promptly without extensive disassembly. Thoughtful design choices contribute to operational reliability and employee safety.

While not exhaustive, here are some notable types of equipment that align with modern facility requirements:

Outdoor enclosures designed to withstand environmental pressures (Outdoor Electrical Distribution Panel)

Angled units enhancing accessibility for dense work areas (Angled Panel Mounted Industrial Socket)

Modular boxes allowing seamless circuit organization (Distribution Socket Box)

Compact systems simplifying control for industrial automation (Industrial MCB Box)

These offerings illustrate the combination of durability, flexibility, and safety, forming the backbone of dependable electrical infrastructure.

As industries evolve, electrical distribution must accommodate new requirements. Integration with automated control systems, incorporation of energy-efficient components, and compliance with updated safety standards are all essential. Flexible layouts and modular interiors support gradual upgrades, ensuring long-term relevance. Facilities that prioritize adaptable designs find themselves better equipped to handle fluctuating workloads, emerging tools, and revised operational procedures.

A comparative overview can help operators make informed decisions based on specific needs:

| Characteristic | Outdoor Panels | Distribution Boxes | Angled Sockets | MCB Enclosures |

|---|---|---|---|---|

| Environmental Resistance | High | Medium | Medium | High |

| Installation Flexibility | Moderate | High | High | Moderate |

| Space Optimization | Medium | High | High | Medium |

| Maintenance Convenience | High | High | Medium | High |

Evaluating these attributes allows facility managers to identify configurations balancing performance with operational practicality.

Beyond physical equipment, strategic deployment enhances overall efficiency. Positioning units near high-use zones reduces cable length and clutter. Grouping modular systems together enables centralized monitoring. Standardizing components across facilities simplifies staff training, spare part management, and emergency responses.

Choosing equipment built for longevity reduces recurring costs associated with replacements and downtime. Durable materials, modular interiors, and ergonomic designs collectively contribute to extended service life. Even under high-demand conditions, reliable housings maintain structural integrity and safeguard internal circuits, reinforcing both productivity and safety.

| Area | Suggested Approach | Rationale |

|---|---|---|

| High Humidity Zones | Sealed Panels | Prevents corrosion |

| Confined Workspaces | Angled Sockets | Improves operator comfort |

| Expanding Facilities | Modular Distribution Boxes | Supports scalability |

| High Security Areas | Lockable Enclosures | Controls unauthorized access |

This approach ensures equipment not only fits operational needs but also adapts to evolving conditions without extensive redesign.

Experienced manufacturers recognize that balancing safety, usability, and durability is essential. Ergonomic layouts reduce fatigue, clear labeling improves troubleshooting, and robust housings resist environmental stresses. Prioritizing these elements allows facilities to maintain consistent performance while minimizing operational risks.

Modern installations often double as visual indicators of organizational diligence. Clean, well-organized panels, coordinated socket layouts, and tidy cable management convey professionalism. A visually organized setup enhances confidence in operational reliability among staff and visitors alike.

Facilities rarely remain static. Temporary expansions, seasonal projects, or evolving production lines demand flexible electrical arrangements. Modular panels, adjustable mounting solutions, and versatile socket orientations provide operators with freedom to modify setups without complete replacements, aligning investment with long-term strategy.

| Feature | Advantage |

|---|---|

| Removable Panels | Quick internal access |

| Hinged Doors | Easy inspection |

| Visual Indicators | Immediate status awareness |

| Standardized Components | Simplified replacement |

These maintenance-oriented characteristics reduce downtime and ensure staff can respond to potential issues efficiently.

Selecting equipment from a manufacturer dedicated to quality, flexibility, and practical design ensures enduring reliability. Facilities benefit from products that integrate seamlessly into existing layouts, enhance operational safety, and remain adaptable to emerging requirements. Ultimately, partnering with an experienced provider supports both efficiency and long-term planning.

Fly-Dragon Electrical Co., Ltd. stands committed to delivering comprehensive solutions, providing industrial and commercial spaces with dependable, efficient, and thoughtfully designed electrical systems.